Photographs can be seen in our Volvo Gallery

The million dollar computer that crashes all day

22 June 2005

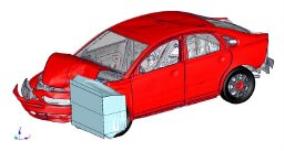

Volvo Cars strengthen its position as the world leader in car safety by commissioning one of the world's most powerful supercomputers for simulating crashes. Using over 300 processors, its capacity is the equivalent of at least one thousand ordinary home PCs.

"Top-class virtual development resources of this type will help us to achieve our aim of making Volvo's real-life cars the safest on the market," says Anders Djärv, head of Crash Simulation at the Volvo Car Safety Centre.

Volvo Cars' latest investment in doubling its virtual crash simulation capacity is a natural continuation of the company's long-term commitment to safety, virtual development and the programme undertaken three years ago to make use of cost-effective Linux clusters.

Volvo Cars has been using a supercomputer since development of the Volvo 850 commenced in 1987. At that time, high-capacity computers were introduced to perform flow, panel pressing and crash simulation calculations.

Overnight performance

The aim throughout has been to develop sufficient capacity to enable the simulation engineers to input test data before going home in the evening so that they have the results the following morning. These can be reviewed together with the design engineers during the day, enabling fresh input data to be prepared for that night. This basically enables work to be carried out around the clock.

The main purpose of the new supercomputer is not to make the calculation process faster, but to enable more and much more advanced calculations to be performed in parallel. If necessary, all of the computing power can be used to perform a single calculation, which can thus be completed in a very short time.

At present, the supercomputer can run a virtual crash text in five hours compared with three days ten years ago, while today's mathematical models are ten times bigger (in other words, more accurate) than at that time.

In addition to maintaining Volvo's lead in car safety, the high computing capacity was basically introduced to meet the demand for shorter product development lead times and lower costs.

Computer simulation cannot fully replace physical crash testing since this is required in the final stages of development work to verify the simulated results and, for example, to verify certain legal requirements. Physical testing and simulation have a somewhat symbiotic relationship and the results of practical testing at the Volvo Car Safety Centre indicate very significant alignment between the two.

Real-life safety

Virtual development is an important element in offering customers what Volvo terms 'real-life safety'; assuring them, in other words, that its cars really are among the safest in the world when they reach the market.

The new supercomputer consists of 151 nodes (IBM eServers 325), each consisting of two CPUs, making a total of 302 AMD Opteron processors. The measured capacity is 1.3 TFlops (peak), making the Volvo Cars installation one of the fastest Linux clusters in the automotive industry. Although a fairly approximate measure, the capacity is equivalent to over 1,000 or so ordinary home PCs!

"The computer provides us with an efficient virtual development facility for optimising and producing robust design solutions", explains Anders Djärv.

"Combined with physical crash testing and over 35 years of investigating real-life road accidents, our supercomputer is an excellent tool in ensuring that our cars provide our customers with 'real-life safety'. Nobody should ever doubt that they are getting one of the world's safest cars when they buy a Volvo."

Legal | Privacy | Contact Us | Search | Site Map

Volvo Owners' Club Limited® 1962-2025